Learn the History of Ferriot

-

Queen Victoria assumes the throne of England and seeks out the finest engravers to carve her Great Seal and other Royal emblems. Finding no suitable talent in Great Britain, the queen dispatches agents to scour Europe. In France, they discover three brothers who leave their homeland to become artisans of the court of Queen Victoria. The French brothers train their offspring to work for the queen as well.

1837 -

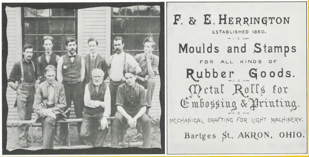

The jewelry company Tiffany’s of New York discovers the talent pool within the queen’s court. Tiffany’s lures the descendants of the French brothers to New York to make dies for ornate medallions and other jewels. One is Frederick E. Herrington.

1850 -

Herrington leaves Tiffany’s and moves to Chicago to start the Art Die Sinking Company. Other family members join him.

1860 -

Dr. Benjamin Goodrich, of the B.F. Goodrich Company, searches out master engravers to produce dies and molds for ornate designs on the sides of solid rubber tires. He discovers the exceptional work of the Art Die Sinking Company, and he convinces Frederick Herrington to close his business in Chicago and move to Akron to work for Goodrich.

1890s -

Herrington reestablishes the Art Die and Sinking Machine Company on Bartges Street in Akron along with his son, Ernest, and his son-in-law, Victor Ferriot.

1900s -

Following their father’s death, two of Victor’s sons, Gene and Glenn, become apprentices at the Mechanical Mold & Machine Co. in Akron.

1920s -

Gene leaves to start his own business in the garage of his home on Storer Avenue. Brother Glenn, a master machinist, joins him, as does brother Albert, a master lens grinder. Later, brother Joseph joins the company, while Albert goes to Hollywood to make camera lenses for the movie industry.

1929 -

By now well established, Ferriot Brothers Inc. patents a unique process that uses beryllium copper — a product of the same beryl ore that produces emeralds — to produce castings of microscopic detail and dimension, yet with the hardness of finely tooled steel.

Started casting rubber molds in beryllium copper.

- Beryllium copper alloy developed in 1933

- Ferriot known worldwide as beryllium copper expert

1934 -

Ferriot Brothers Inc. becomes a pioneer of thermoplastic injection molds for the just-emerging plastics industry. The beryllium copper process allows the company to scale to new heights. Ferriot becomes the number one producer of molds for gas masks for the Allied Forces in World War II as well as the number one producer of small bullet-casing molds.

1940 -

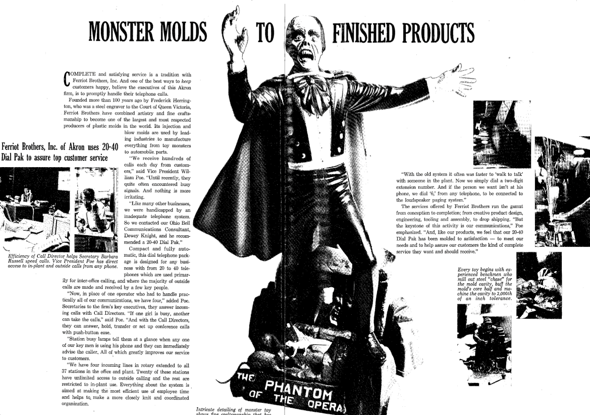

Ferriot Brothers Inc. establishes an injection molding division — actually producing parts, in addition to molds, mainly for the toy industry. Ferriot makes dolls, model planes, ships, cars and other novelties for toy makers Mattel, Kenner and Marx.

1946 -

Ferriot becomes a major supplier of highly detailed plastic components for furniture, including cabinetry, chair backs and ornate legs.

1950s -

Joseph Ferriot, then president of the company, receives the award of Life Fellowship in the Royal Society of Arts of London, one of the highest international honors for creative arts. A sculptor, etcher and painter, he created the plaster models that served as impressions for dolls and other products. His models shaped both rubber and plastic molds.

1959 -

Produced molds for furniture industry. Molded and primed parts for furniture industry.

1960s -

The Ohio Edisonian, a publication of the Ohio Edison Company, reports that Ferriot Brothers Inc. “has become the largest producer of toy molds in the world.” Counted among its customers was The Walt Disney Company, which turned to Ferriot for the first rubber molds for Mickey and Minnie Mouse and Donald Duck.

1963 -

Ferriot establishes a finishing assembly division.

1965 -

Ferriot designs and carves wooden models, which then undergo a casting process to produce injection molds for the “front doors” of 21-inch wooden television cabinets. Ferriot produces and paints these intricate front sections for RCA, Zenith and Admiral. In 1971, RCA thanks the company for 121 truckloads of front panels without a single reject.

1970s -

IBM engages Ferriot to produce injection molds, tooling and decorative paint finishes for its original personal computers. The relationship with IBM launches Ferriot into the computer and business-machine industry. Later, the company paints the original Apple Macintosh. Ferriot remains a leading supplier in this sector.

Started molding structural foam

- Built molds for structural foam

- Molded, EMI/RFI Shielded and painted

7,000,000 IBM PC-1/PC-2 Keyboards Bezel

7,000,000 IBM PC-1/PC-2 Drive Units- General Electric recommended Ferriot as one of their top 10 structural foam molders in the US

1978 -

Ferriot becomes heavily involved in metal to plastic conversions. Engineered resins and structural foam process enable weight and cost savings.

1980s -

Ferriot adds a rapid services division.

1994 -

Ferriot added gas assist injection molding process to their list of capabilities.

- Faster cycle

- Reduced painting costs

1995 -

Concentrated on large OEM electro-mechanical assemblies.

- Product with 340+ sku’s

- Product with 390+ sku’s

- Developed and manage worldwide supplier base

2000s -

Ferriot introduced first proprietary product in over 40 years.

- Thermoplastic Architectural Siding for construction industry

2007 -

Ferriot introduces a proprietary injection molding product, American Original Shake & Scallop Siding: injection-molded architectural shake-shingle siding for the construction industry. The company sells the siding under its wholly owned subsidiary, American Original Building Products LLC.

2008 -

Ferriot implements Delmiaworks Manufacturing ERP Software for end-to-end supply chain and manufacturing intelligence (formerly IQMS).

2015 -

Ferriot’s largest press is installed, a Negri Bossi BI-POWER VH2000-22500 Injection Molding Press (2,250 ton).

2018 -

New Tech: Ferriot expands quality capabilities with new high precision optical 3D scanner.

2018 -

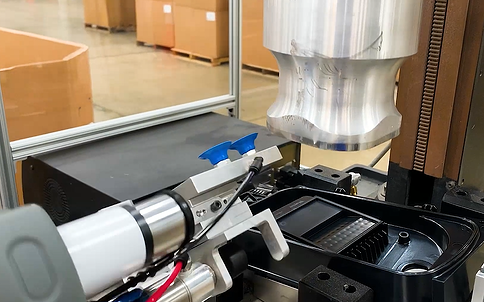

Incorporated the use of COBOTs to improve manufacturing efficiency.

2020 -

New Tech: Ferriot adds more branding and logo capability with a flatbed, multi-color inject printer.

2020 -

Ferriot celebrates 95 Years as “Your Partner in Plastic” (95th Anniversary – June 2024).

2024

Further Reading

About Us

Goals and Values

Plastics Machinery & Manufacturing

Automation Boosts Molder’s Production

Plastics News

Ferriot’s 90-year Story of Reinvention

Ferriot Blog

Molding History: “Forever Thankful for What They Were Able to Contribute”

MeritMatters (PDF)

A Long History – How Ferriot Continues to Live Up to Its Legacy

US Department of Defense

During WWII, Industries Transitioned From Peacetime to Wartime Production