Expert Manufacturing Process Qualification for Plastic Parts

Manufacturing Process Qualification for Plastic Parts

Efficient Processes. Quality Standards.

Whatever the product is, there is an optimum process for making it efficiently with adherence to quality standards.

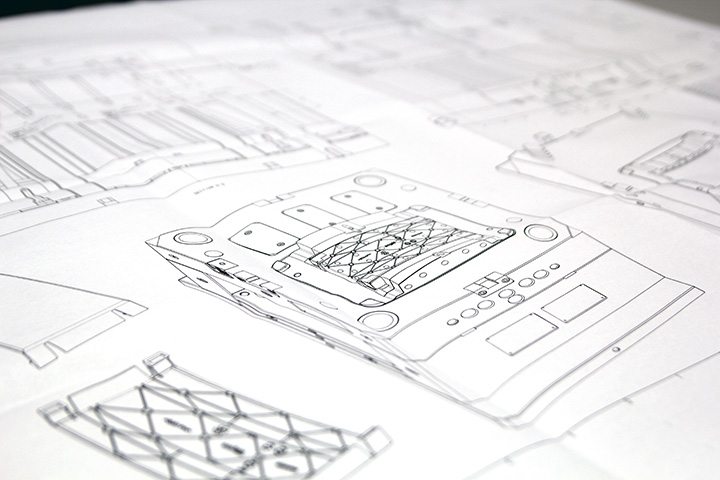

Ferriot’s design and engineering team creates the custom manufacturing instructions that are critical to turning out finished products that meet high quality standards.

Experience makes all the difference.

Ferriot’s reputation for superior quality is founded in the skills of our designers and engineers, as well as our seasoned manufacturing teams. After all, a finished product can only be as good as the detailed steps and ingredients that go into its production and assembly. This is where a seasoned team makes the difference — in determining everything from the molding and component requirements to the specifications for painting and decorative finishing.

Process Qualification goes beyond the production of parts and into our sub-assemblies and assemblies. Having a clearly documented process and trained, qualified associates are critical components to everything we do. Read the case study Contract Manufacturing for Digital Printers to learn more.

About Contract Manufacturing at Ferriot

Our expertise includes engineering, product design, injection molding, custom molding, sub- and finished assembly and on-time delivery of components and finished products for major industry. We streamline the total manufacturing process from start to finish, from supply line development and management, process qualification, product testing and final assembly, all the way to drop shipping.

With mobile, adaptable manufacturing modules, Ferriot tailors on-time production to vastly different needs, including short-runs on assemblies with multiple parts.

Institutional Experience for the Manufacturing Process Qualification Process

With over 85 years of institutional experience, a trained workforce averaging nearly 20 years of experience per employee, and a 200,000-square-foot facility, Ferriot runs multiple assembly lines around the clock. Our quality-control extends to every product we turn out. Our workers know the rules: With every new set of part prints and specifications, they must train and demonstrate proficiency in the task at hand in order to participate in an assembly.

In products ranging from medical devices to business machines, Ferriot delivers consistent quality, on time, at competitive prices and with the convenience and efficiency of one-stop shopping.

Even if you don’t know us, you’ve probably touched our products — in banks, at gas pumps, in offices, industry and hospitals.

Worksheet Which Injection Molding Technology is Right for You?

Download WorksheetCase Studies

How can we help?

Ferriot’s experienced engineers are here to guide you through every critical step in your injection molding journey, from concept to completion.