The Power of Integration: Driving Efficiency in Contract Manufacturing with End-to-End Solutions

Contract manufacturing has evolved far beyond simple part production. Today’s OEMs require manufacturing partners that can deliver comprehensive solutions that optimize production efficiency, streamline supply chains and enhance product quality.

Injection Molding Resin Selection Workbook

Choosing the right resin is critical to injection molding success. This workbook helps OEMs navigate the complexities of material selection to balance mechanical performance, cost, compliance, and end-use requirements.

Considerations to Take When Making Plastics for a Medical Setting

Medical plastic components must meet demanding standards for safety, compliance, and performance. We've outlined the key considerations OEMs should evaluate early in the design process to ensure successful outcomes in regulated medical environments.

Seamless Tool Transfers: How Ferriot Helped Ensure Uninterrupted Production for SRG Global Inc.

SRG team members were not only seeking a reliable injection molder, but one that could manage the intricacies of the mold transfer portion of the program with minimal disruption.

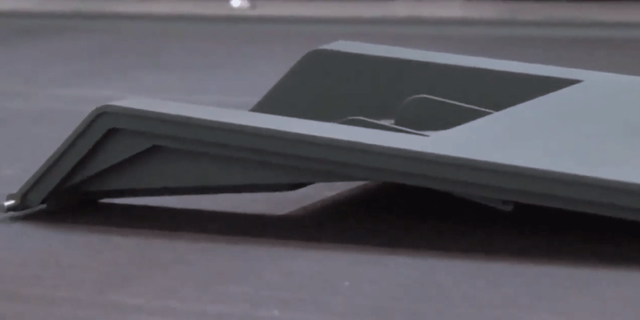

6 Advantages of Structural Foam

Structural foam is a manufacturing material which pairs a foamed core with a solid outer layer. It is lightweight and flexible but maintains the good strength and stiffness compared with traditional polymers. Here is a video of the top 6 advantages when thinking about structural foam.

The Smart Move—Transferring Your Injection Molds to Ferriot

Considering a mold transfer for your business? Look no further than Ferriot. With decades of industry expertise, we specialize in facilitating seamless transitions for businesses looking to relocate their mold tooling to a new injection molding partner.

Injection Molding Tool Transfer Resources Guide

Being fully educated about the entire mold transfer process is the first step toward success. In many cases, it becomes essential to have a supplier that does more than shoot-and-ship injection molded parts; and the solution requires a full-service custom injection molding manufacturer with a highly experienced engineering team that deals with the development, design, quality assurance, and production challenges on a daily basis.

Innovation in Action: Cobots Transforming the Injection Molding Industry

Great operators are often wasted on repetitive manufacturing processes, where most of their time is spent on mundane tasks instead of work that requires more "brainpower" and finesse. If operators are being forced to act like a machine doing the same thing over and over again, why not get an actual machine to do it? That’s the idea behind automation and using collaborative robots, known as cobots, on the manufacturing floor.

Designing Injection Molded Parts: A Handbook for Designers & Engineers

Injection molding is a highly-engineered process that demands careful planning and attention to detail if your finished product is to achieve its full potential. This handbook will help you understand the most important aspects about working with injection molding contract manufacturers so you can work together to make the best possible decisions throughout the product design and development process.

Mastering the Shift: 7 Key Points for Smooth Injection Molding Supplier Transitions

When deciding to move injection molds from one supplier to another, there are seven key points you should consider in advance. It takes communication, precision, and above all experience. We have listed out everything from inventory to cosmetic standards and we hope it helps you with a successful transition.

How to Make Smart Injection Molding Resin Selections

In this Injection Molding Resin focused webinar, the experts at Ferriot will help educate on the most critical considerations for choosing resin. The Ferriot team will walk you through the selection process, the mathematical implications, the chosen aesthetic, and the best technology for your project. Please enjoy.

Structural Foam Injection Molding Resource Guide

Are you trying to discover methods to create stronger plastic parts? If the answer is yes, structural foam can be the answer. Ferriot has created this initial Guide leveraging our decades of experience in structural foam injection molding. The Guide will walk you through differences in the category and how, if done correctly, it can produce a lighter, stronger, and lower cost part. This Guide is key to making an educational choice about the traditional ways to create parts and the structural foam way to create parts.

Top 6 Advantages of Structural Foam

Structural foam is a manufacturing material which pairs a foamed core with a solid outer layer. It is lightweight and flexible but maintains the good strength and stiffness compared with traditional polymers. Here is a list of the top 6 advantages when thinking about structural foam.

Worksheet: Considerations to Take When Making Plastics for an Industrial Setting

When making plastics for an industrial setting, there are some specific considerations that need to be taken. Our worksheet contains eight high-level questions.

Creating Injection Molded Parts that Shine

Injection molded parts that shine with chrome finishing can provide a level of corrosion protection, makes cleaning the surface easier, and increases the part’s overall durability. But chrome finishing should never be an afterthought; careful planning is required to ensure the shiny, mirror-like shine you want.

Contract Manufacturing Guidelines

By using this worksheet, prior to discussing contract manufacturing options you'll find 7 steps for a successful relationship and end product and a deeper understanding of how it benefits your core business.

Ferriot Injection Molding Checklist

Watch the Injection Molded Checklist video for the 10 questions every designer should ask before beginning an injection molding project.

Negri Bossi BI-POWER VH2000-22500 Injection Molding Press Installation

Watch the time-lapse video showing the installation of our new 2,250-ton press from its delivery via five semi-trucks to operational testing of the KUKA multi-function robot’s automation capabilities.

Insert Molding: Safety and Consistency Through Automation

Ferriot's core expertise in injection molding is perfectly exemplified in their innovative insert molding process. Insert molding is the placing of an object (insert) into an injection mold and then encasing some portion of it in plastic.

Insert Molding

Ferriot's expertise in injection molding is exemplified in their innovative insert molding process. Insert molding is the placing of an object (insert) into an injection mold and then encasing some portion of it in plastic. Using automated processes Ferriot minimizes the variables that affect final part quality by ensuring a consistent, reliable, and repeatable process.

Ferriot MAPP Safety Video Submission

This employee safety training video is intended to build a safety culture by encouraging employees to take an active role in safety in their work environment. If you see something, say something.

American Original Building Products

American Original Shake and Scallop Siding lives up to the true spirit of America. It’s traditional in looks and appeal, yet innovative in craftsmanship and installation efficiency.

Worksheet: Considerations to Take When Making Plastics for a Medical Setting

When creating plastics for a medical setting, there are some specific considerations that need to be taken. Use this worksheet to help you to get better clarity about your project and assist you with identifying areas where more research is needed.

The Injection Molded Checklist

There are ten key questions designers must have the answers to for a successful conversion from other materials to resin injection molding. Whether the design is for medical devices, business machines or for an industrial application, arm yourself today with this valuable infographic checklist.

How Injection Molding Happens: The Step by Step Production of a Medical Device Part

At Ferriot, we’ve carved out a particular manufacturing niche: making housing enclosures for the medical market. How different is the process of creating medical grade parts? Relevant for any manufacturer or engineer, this PDF addresses the unique challenges of fabricating a plastic part that is destined for a critical role in the care of someone’s loved one.

Seven Ways to Cut Costs on Injection Molded Parts

With injection molding, a variety of factors affect a part’s final cost, including part design, production time, the temperature and pressure used, and the type of plastic resin chosen. However, there are bigger issues to consider long before your part is in the mold. This guide addresses specific ways you can trim costs as you embark on your next custom injection molding project. Following these best practices will go a long way toward minimizing part costs without compromising your design goals.

Which Injection Molding Technology is Right for You?

We have the ability to use five different injection molding technologies for a project. But how do you know which is the best for your project? This worksheet walks you through the different injection molding technologies and points you towards the best fit.

Pad Printing Services: 3 Common Problems to a Centuries-old Process & 3 Simple Solutions

Despite its straight-forward process, pad printing can present a few snags that will affect the finish and polish on your final product. That’s why our experts have created this white paper to address the three most common pad printing process problems and how to fix them.

The Tips, Tricks, and Traps of Injection Molding Resin Selection

Every injection molding project begins with resin selection and finding that right balance between cost, performance, moldability, and function. Regulatory compliance, environmental considerations, resistance to temperatures or impact – you know the questions. This white paper on proper resin selection can provide many of the answers.

Finishing Operations for Fluid-Injection Pumps

As a full-service contract manufacturer, Ferriot is capable of a wide variety of services to the customer. Learn how a medical OEM selected Ferriot for full-service sourcing and assembly of components for fluid-injection pumps.

Finishing Operations for Wheelchair Components

Lead times can be problematic if not managed correctly. We’ll show you how we worked with a medical device OEM to shorten lead times on parts and components for wheelchairs, and gain greater efficiencies.

Contract Manufacturing for Vacuum Air Tube Units

When you have hard fast deadlines, it’s often necessary to drop ship the finished products directly to end users. Learn about the details of the logistics of this project and how drop shipping an order can be completed effectively.

Contract Manufacturing for Digital Printers

A Fortune 500 OEM needed enclosures for an 8,000-pound digital printer. Ferriot was able to use our expertise in testing and quality procedures to organize the framework for 31 different components, and manage the supply chain process that delivered over 450 parts to the project.

Injection Molding for an Alternative to Wood Shake Siding

Ferriot has innovated a high-quality alternative to wood shake siding. This study illustrates our design and engineering expertise in creating quality residential home materials.

Injection Molding for Fuel Pump Nozzles

Converting from metal to plastic can be tricky. Learn how a fuel pump OEM saved on the move without compromising quality.

Custom Mold Manufacturing for Infusion Pumps

With painting the finished products no longer an option, an original equipment manufacturer (OEM) reached out to Ferriot for help during the product development phases of its new infusion pumps. The OEM needed a partner who could not only provide a sleek finished product, but also assist with the overall functionality of the new products.

Custom Mold Manufacturing for Video Conferencing Units

In order to meet deadline for its video conferencing units, a Fortune 1000 original equipment manufacturer reached out to Ferriot, Inc. for assistance. Not only did these video conferencing units need to be in top working order starting with the first unit, but they also needed to be designed for indoor and outdoor applications. No small feat when 28 different plastic parts are required.

Getting Structural Foam Molding Right Takes More than Just Blowing Bubbles

One of the biggest challenges in any new product development effort is identifying skilled people who can contribute significantly to the project, including the vendors who support the process. Ensuring the success of a new product demands the freedom to use new materials and new suppliers, as complex design and production challenges arise.

Transforming Injection Molding Vendors into Injection Molding Partners

Increasingly, design engineers and their employers are looking for vendors that they can partner with over the long term for help with issues like part design/optimization, tooling modifications or simplification, resin selection, cost containment, just-in-time delivery, and special finishes to name but a few.