The world of injection molding is evolving rapidly, driven by advances in manufacturing technology, materials science, and sustainability initiatives. For OEMs, staying ahead of these trends isn’t just about adopting the latest gadgets or resins — it’s about ensuring that parts are produced efficiently and with long-term performance in mind.

With advantages such as smart manufacturing systems with real-time process monitoring and advanced thermoplastics that expand design possibilities, OEMs can enhance quality, mitigate risk, and accelerate time-to-market.

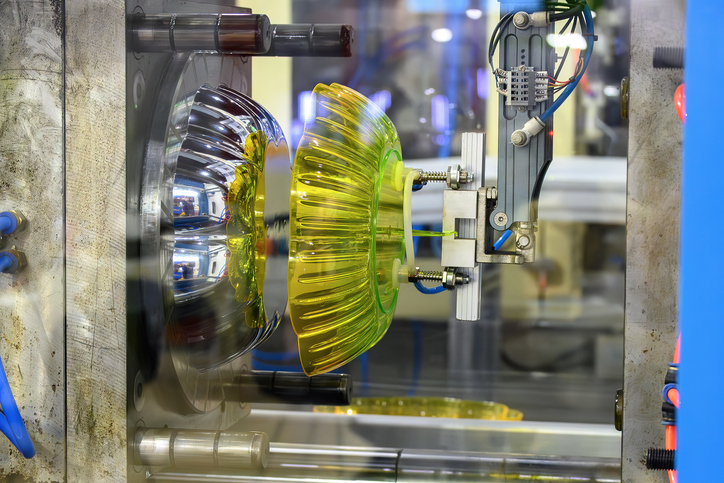

Let’s explore some of the key trends in injection molding that are shaping the future, including automated production, advanced materials, sustainable solutions, and how a forward-thinking partner like Ferriot helps OEMs leverage these advancements for complex, high-performance components.

Smart Manufacturing and Digital Integration in Injection Molding

Industry 4.0 may be a buzzword, but it is genuinely transforming how injection molding operations are managed. Real-time data collection, machine learning, and IoT integration allow manufacturers to optimize every stage of production, from cycle times to quality monitoring. Predictive maintenance reduces unexpected downtime, while analytics help minimize scrap and improve consistency across high-volume runs.

At Ferriot, we have invested in state-of-the-art injection molding equipment and integrated program management systems to leverage these smart manufacturing capabilities. By connecting machines, monitoring production metrics, and streamlining communication with OEM partners, Ferriot delivers parts faster, with higher quality and less variability.

Advanced Automation and Robotics on the Production Floor

A core pillar of Industry 4.0, automation has transformed injection molding by improving efficiency in part handling, inspection, and secondary processes. Robotics in particular reduces human error and supports scalable production across varying volumes.

For OEMs, this means predictable lead times and the ability to respond quickly to market demands. Ferriot combines automation with in-house secondary services such as assembly, decorating, and testing, ensuring that finished components meet precise specifications without the delays often caused by multiple vendors or hand-offs.

Material Innovation: Engineered Thermoplastics and Sustainability

High-performance thermoplastics are becoming increasingly important in medical, industrial, and business equipment applications. These materials offer improved strength, chemical resistance, and temperature tolerance, enabling OEMs to design parts that last longer and perform under demanding conditions.

At the same time, there is a growing emphasis on sustainability. Recyclable, bio-based, and lower-emission materials are now entering mainstream production. Ferriot’s expertise in material selection and processing ensures OEMs can incorporate advanced polymers that balance performance, compliance, and environmental considerations, without compromising manufacturability or precision.

Design for Manufacturability (DFM) in a High-Tech Era

The integration of advanced materials and automated processes makes early design collaboration more critical than ever. DFM practices help engineers anticipate potential manufacturing challenges, optimize part geometry, and reduce cost and risk before tooling begins.

Ferriot works closely with OEMs to provide DFM guidance and, mold flow analysis. This collaborative approach ensures parts are designed for manufacturability while maintaining high performance and reducing the need for costly late-stage revisions.

Looking Ahead: The Evolving Role of the Injection Molder

Modern injection molders are no longer just component producers; they’re strategic partners. OEMs increasingly rely on molders to provide expertise in design, material selection, quality assurance, and supply chain management.

Ferriot embraces this expanded role, offering end-to-end program support that covers everything from engineering collaboration and precision molding to finishing, assembly, and logistics. By staying at the forefront of trends in injection molding, Ferriot helps OEMs deliver high-quality, durable parts while reducing risk, accelerating time-to-market, and future-proofing production.

Partner with Ferriot for Future-Ready Injection Molding

OEMs who anticipate and adapt to these trends can gain a competitive advantage in product performance, reliability, and sustainability. Ferriot’s combination of advanced technology, material expertise, and full-service manufacturing positions OEMs to take full advantage of these innovations.

If your team is looking to leverage the latest trends in injection molding for smarter production, faster development cycles, and high-performance components, contact Ferriot today to explore how our future-ready capabilities can support your next project.