Keeping a competitive edge in today’s market requires speed and agility when launching new products. Time to market for new products has become further and further compressed. Early engagement with a full service plastics partner can steam-line your development process and accelerate your time to market.

Here are six ways a full-service plastics partner can help your business reduce time to market for new products.

Design Assistance

Have you ever experienced making samples of a new product on a 3-D printer and then being told that the product was not manufacturable? By engaging a plastics partner in the initial stages of your design you can save hours of effort. A plastics expert can provide input on what design features are possible from a manufacturing standpoint. This will allow you to design with manufacturability in mind and save hours of effort by eliminating the number of design iterations required. A plastics partner should be in integral part of a collaborative process with all stakeholders in new product development.

Have you ever experienced making samples of a new product on a 3-D printer and then being told that the product was not manufacturable? By engaging a plastics partner in the initial stages of your design you can save hours of effort. A plastics expert can provide input on what design features are possible from a manufacturing standpoint. This will allow you to design with manufacturability in mind and save hours of effort by eliminating the number of design iterations required. A plastics partner should be in integral part of a collaborative process with all stakeholders in new product development.

Custom Mold Manufacturing

Designing an injection mold is both an art… and a science. Working with experienced Tooling Engineers is critical to creating an optimal mold design and optimizing the development process. Experienced engineers will consider how best to accomplish all design aspects of a mold. A qualified engineer will consider options that include identifying actions to create part features, holes, recessed features, windows and inclusion of inserts. A well designed mold can eliminate additional steps in the manufacturing process later.

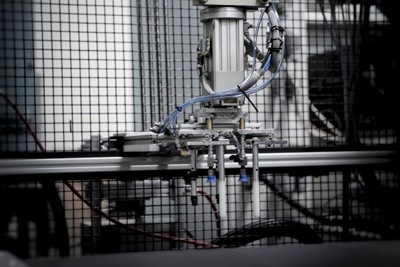

Injection Molding

Picking an injection molding company that has multiple injection molding processes will improve your chances of getting the best process for your part.

These would include straight injection molding, structural foam molding, gas assist molding, insert molding and over-molding. Each process has its own attributes that will satisfy particular product needs. A qualified plastics partner can help you to identify the ideal method to provide a quality part.

Finishing Operations

Most plastic parts will require some form of finishing such as pad printing, ultrasonic insertion, hot stamping, painting or EMI/RFI shielding. Selecting a plastics processor that includes these operations under the same roof will provide the most efficient manufacturing process. This can take weeks out of the lead time to produce a finished part.

Contract Manufacturing

Utilizing a plastics partner that can also source components and provide assemblies can simplify the OEM’s manufacturing process and drive cost savings. By providing supply line development and management, your plastics partner can economically source materials from qualified suppliers, reducing supply chain risk for the OEM. Assembly capability under one roof provides cost savings by eliminating additional shipping and assembly cost.

Total Quality Management

Engaging with a plastics specialist can help your company achieve optimum efficiency and profit while producing quality parts. Whether you are taking a product from concept to completion or transferring an existing mold project, effective quality management practices are an important factor. A qualified plastics partner has procedures in place for mold, part and process qualification and has documented processes that will ensure production quality. Trained & experienced engineers will follow standard testing methodologies including FMEA methods and utilize the right testing equipment for part qualification.

Optimizing your new product development process is a strategic imperative where the first to market with a new product enjoys a competitive advantage. Engaging a qualified plastics partner early in the new product development process can help you to accelerate your time to market by saving time and investment cost and delivering a quality product.