In the dynamic landscape of modern manufacturing, few technologies have left as profound a mark as large tonnage injection molding. This innovative process has unlocked the doors to an array of industries, allowing for the creation of intricate, high-quality plastic components on a grand scale. The efficiency injection molding provides delivers high volume production with precision that ensures consistency in the quality of each part. From the automotive sector to healthcare, packaging to aerospace, the applications of large tonnage injection molding are as diverse as they are impressive. In this blog, we delve into the world of applications for this transformative technology, uncovering how it has revolutionized various sectors.

Automotive Industry

The automotive industry is perhaps one of the most notable beneficiaries of large tonnage injection molding. This technology has redefined the way vehicles are designed and manufactured. From sturdy bumpers to finely crafted interiors, large tonnage injection molding enables the creation of complex parts that offer both aesthetic appeal and structural integrity. Moreover, as the industry pivots towards electric vehicles, this technique plays a pivotal role in producing lightweight yet durable battery housings, contributing to the evolution of sustainable transportation.

Aerospace Advancements

In aerospace, precision and reliability are paramount. Large tonnage injection molding has risen to the challenge by producing components that meet stringent safety and performance standards. The technology is instrumental in crafting lightweight parts for aircraft interiors, including seating systems, overhead compartments, and ventilation controls. By ensuring consistent quality and dimensional accuracy, large tonnage injection molding plays a vital role in enhancing passenger comfort and aircraft efficiency.

Consumer Goods Revolution

From household appliances to sports equipment, consumer goods encompass a vast array of products that benefit from large tonnage injection molding. This method allows manufacturers to create intricate designs, ensuring optimal functionality and precise fitting. The ability to produce large-scale appliances, furniture components, and electronic enclosures with exceptional detail has reshaped the consumer goods industry, setting new standards for both form and function.

Healthcare Innovation

Large tonnage injection molding is a game-changer in healthcare, driving the production of critical medical devices and equipment. The production of medical devices, such as diagnostic equipment, patient monitors, hospital beds and imaging systems, demands parts that meet stringent standards for hygiene, accuracy, and reliability. Additionally, this technique contributes to the advancement of medical technology by facilitating the production of large-scale, intricate parts for devices such as MRI machines and radiation therapy equipment.

Packaging Reinvented

In the world of packaging, large tonnage injection molding has introduced a new era of design possibilities and durability. Rigid containers, closures, and packaging designs with complex geometries can be manufactured with exceptional accuracy and consistency. This capability not only enhances the aesthetics of packaging but also ensures the protection and preservation of contents, catering to the needs of diverse industries. Packaging is often designed to be reused, over and over again, providing a better alternative to other materials that are single use.

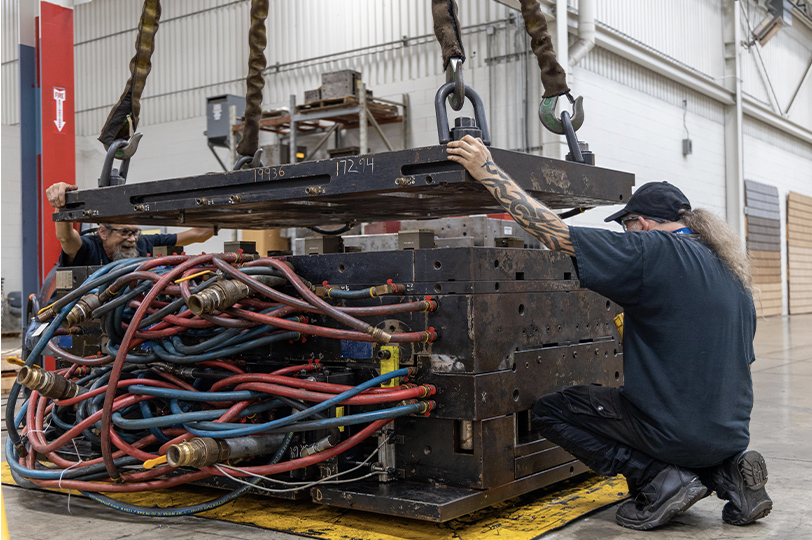

Industrial Strength

Industrial equipment and machinery often require robust and intricate plastic components. Large tonnage injection molding rises to this challenge, producing parts that withstand rigorous industrial environments, indoors and out. From heavy machinery housings to components in automated manufacturing lines, this technology contributes to the efficiency and reliability of industrial operations.

Electronics Evolution

The electronics industry demands both precision and adaptability. Large tonnage injection molding rises to the challenge by producing oversized casings, enclosures, and structural components for electronic devices. Whether it’s the housing for a sophisticated medical imaging device or a robust enclosure for industrial control systems, this technique ensures that electronic equipment remains protected and functions optimally in various environments. The ability to accommodate intricate designs and integrate features such as cooling mechanisms further enhances the applicability of large tonnage injection molding in the electronics sector.

The applications of large tonnage injection molding are far-reaching and impactful. Across industries, this technology has redefined manufacturing possibilities, enabling the creation of intricate, high-quality plastic components that drive innovation, functionality, and sustainability. As technology continues to advance, we can only anticipate that the scope of applications for large tonnage injection molding will expand, opening up new horizons for industries worldwide.

Are you ready to embark on your journey towards mastering large-scale injection molding? We’re here to guide you every step of the way. Don’t hesitate to reach out to Ferriot Inc., a large tonnage contract molder manufacturer to discuss your upcoming large parts projects. Let’s explore the vast potential of this innovative landscape together! Contact us today and bring your ideas to life.