Thanks to its strength and versatility, structural foam molding is a go-to solution for many high-performing industries. For OEMs in those industries, controlling costs is always a top priority. From material selection and part design to tooling strategies and process optimization, there are multiple opportunities to reduce expenses during the structural foam molding process.

In this blog, we’ll explore practical strategies to optimize efficiency, improve part quality, and maximize ROI while leveraging the unique advantages of structural foam molding.

Understanding the Structural Foam Molding Process

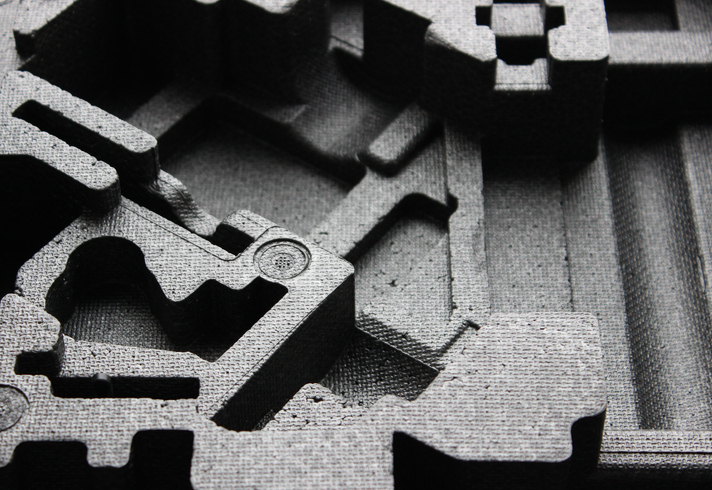

Structural foam molding is a specialized injection molding technique that combines a standard thermoplastic resin with a chemical blowing agent to create a cellular, lightweight core. During the injection phase, the blowing agent expands, forming a foam-like internal structure while the outer walls remain dense and solid. This approach produces parts that are strong yet lighter than fully solid components, making them ideal for large enclosures, housings, and industrial equipment where rigidity, dimensional stability, and weight reduction are critical.

OEMs often select structural foam molding over traditional injection molding when part size, weight, or material efficiency are major considerations. The process allows for larger molded components without the need for excessively large tonnage presses or thick-walled parts, providing a practical and cost-effective solution for complex, high-volume projects.

Key Cost Drivers in Structural Foam Molding

Several factors influence the overall cost of structural foam molded parts. Material usage is a primary consideration: selecting the right resin and filler combination can reduce both part weight and raw material expenses, while options like recycled content can further enhance cost efficiency.

Tooling represents another significant investment. The design, precision, and expected lifecycle of the mold impact both upfront costs and long-term production efficiency. Optimizing mold design can extend tool life and reduce maintenance downtime.

Cycle times and machine efficiency also play a critical role in controlling costs. Efficient press operation, proper temperature control, and consistent foam expansion ensure repeatable production while minimizing scrap. Finally, secondary operations — such as painting, decorating, or assembly — can add time and expense, making it important to plan finishing processes alongside part design.

Design Strategies That Reduce Cost

Thoughtful design is one of the most effective ways to reduce costs in the structural foam molding process. Design for Manufacturability (DFM) principles help engineers optimize wall thickness, minimize unnecessary material, and integrate multiple features into a single part, reducing assembly steps and material waste.

Consolidating parts and incorporating functional features — such as ribs, bosses, or mounting points — directly into the mold can eliminate secondary operations and simplify assembly. Ferriot’s engineering team collaborates with OEMs early in the design process, using mold flow analysis, structural evaluation, and material expertise to ensure that molds are both efficient to produce and capable of consistently high-quality output.

Process Optimization for Efficiency

Modern equipment and advanced process monitoring are key to achieving cost savings in structural foam molding. Shortening cycle times without sacrificing part quality increases throughput and reduces overall production costs. Industry 4.0 practices, including predictive maintenance and real-time process monitoring, help prevent downtime, maintain consistency, and reduce scrap.

Implementing rigorous quality control and process optimization ensures that parts meet specifications on the first pass, minimizing rework and waste. By combining engineering expertise with advanced machinery and a focus on efficiency, OEMs can maximize the value of structural foam molded components while controlling production costs.

Experience the Value of Partnering with the Right Molder

Reducing costs in the structural foam molding process isn’t just about materials or cycle times — it starts with the right manufacturing partner. An experienced molder like Ferriot brings deep expertise in in-house mold design, structural foam molding for large and complex parts, and integrated secondary services such as assembly, painting, and decorating.

Strong program management ensures that projects stay on schedule, costs are controlled, and risks are minimized throughout production. By collaborating early and closely with OEMs, Ferriot helps align design, materials, and process strategies to achieve high-quality, cost-efficient results without compromising performance.

Looking to optimize your next structural foam molding project? Contact Ferriot to explore practical, cost-saving solutions that deliver durable, precise, and efficient parts.