Manufacturing has always been a competitive industry and it’s only becoming more so. To stand out, many OEMs are pursuing ways to improve performance while keeping costs under control. One strategy that has gained a lot of momentum in recent years is converting metal to plastic parts. Components like industrial enclosures, medical device housings, and electronics casings can benefit from high-performance polymers, which deliver tangible advantages in weight reduction, production efficiency, and total cost of ownership.

At Ferriot, we’ve helped OEMs across a wide range of markets make the transition from metal to plastic with confidence. Our deep expertise in material selection, custom injection molding, and value-added assembly allows us to guide customers through the conversion process, from early-stage part design to full-scale production.

Let’s explore how replacing metal with plastic can unlock real ROI, without compromising durability or function. Whether you’re rethinking legacy parts or developing a new product line, understanding the benefits of engineered plastics is a smart move for your bottom line.

Understanding the Shift: Why OEMs Are Replacing Metal with Plastic

As manufacturers face growing pressure to improve margins, reduce product weight, and meet sustainability goals, the shift from metal to plastic parts has become a strategic priority. Often referred to as “material conversion”, this trend isn’t just about reducing raw material costs. It’s about rethinking product design for long-term value and manufacturability.

Lightweighting initiatives, for instance, are pushing OEMs to look beyond metal, especially in sectors like industrial automation, medical devices, and electronics, where ease of handling and portability are key. At the same time, plastic components are often faster to mold and easier to assemble, supporting faster production cycles and greater scalability.

Still, some decision-makers hesitate to make the switch, concerned that plastic won’t deliver the same durability or longevity. But thanks to advancements in high-performance thermoplastics (such as glass-filled nylon, polycarbonate, and PPS) those assumptions no longer hold true. These engineered materials can match or even exceed metal in areas like tensile strength, chemical resistance, and dimensional stability.

The Advantages of Converting Metal to Plastic Parts

Cost Savings: Material, Manufacturing, and Lifecycle

When considering metal to plastic parts conversion, many OEMs focus on the immediate savings in raw material costs. But the total cost of ownership (TCO) is the more important metric. Plastics, particularly engineered thermoplastics, can deliver substantial savings not only in the raw material cost but also in the manufacturing process. The flexibility of plastic injection molding often eliminates the need for costly secondary operations such as welding or machining, reducing both production time and labor costs.

On top of that, the tooling required for plastic parts is generally more cost-effective, especially in high-volume production runs. Plus, there are significant advantages to plastic components over the lifecycle of the product, including corrosion resistance and lower long-term maintenance costs.

Weight Reduction and Performance Enhancements

One of the most immediate and visible benefits of converting metal to plastic parts is the weight reduction. Lighter parts translate directly into cost savings, especially in industries like electronics, automotive, and medical devices, where shipping and energy efficiency are critical factors. Reduced weight not only lowers transportation expenses but can also improve the overall energy efficiency of end products, making them more appealing in today’s environmentally-conscious market.

Beyond lighter weight, today’s engineered plastics deliver impressive mechanical properties. With options like glass-filled nylon or polycarbonate, parts made from plastic can rival metals in terms of tensile strength, impact resistance, and heat tolerance.

Moreover, plastic molding offers opportunities for value-added features that are difficult or impossible to achieve with metal. Think integrated fasteners, internal ribs for added strength, and even overmolding for enhanced ergonomics or multi-material functionality. All of these are made possible through the design flexibility of plastic injection molding.

Design Flexibility and Functional Benefits

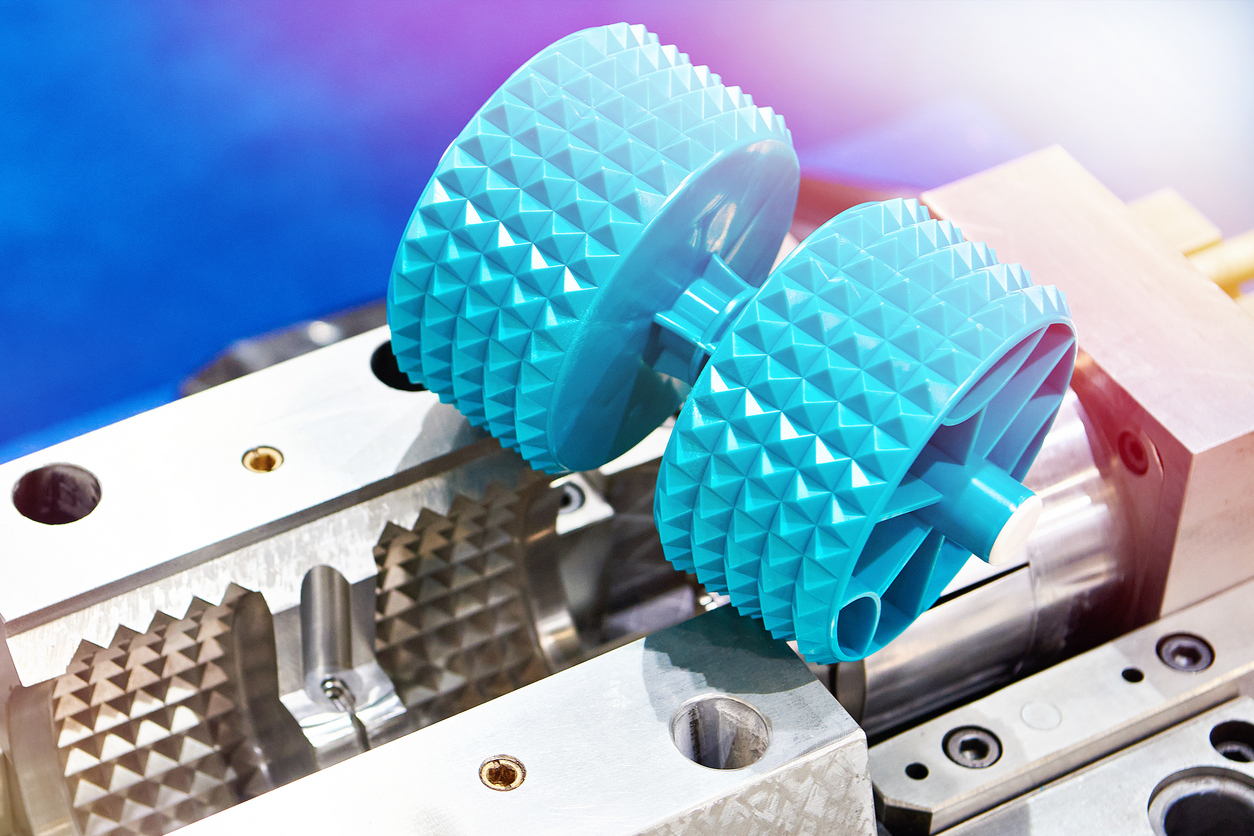

Plastic injection molding allows for far more complex geometries than metal working techniques, enabling OEMs to consolidate multiple parts into a single molded component. This design freedom reduces the number of pieces in an assembly, simplifying the supply chain and improving overall product performance.

Plastic also offers tremendous opportunities for functional enhancements, including ergonomic improvements and aesthetic upgrades. Multi-material assemblies, such as soft-touch overmolded grips or integrated electrical components, provide both tactile comfort and additional functionality in a single part. Custom finishes — such as matte, glossy, or textured surfaces — can also be incorporated directly into the molding process, eliminating the need for additional post-production work.

At Ferriot, our use of structural foam and gas-assist molding techniques further illustrates how plastic can replace metal without sacrificing strength. These specialized molding processes allow for large, lightweight parts that still deliver exceptional structural integrity, all while maintaining the advantages of plastic, such as reduced weight and manufacturing flexibility.

Evaluating ROI: What OEMs Should Consider

Replacing metal with plastic can deliver measurable ROI — but only when the decision is based on smart financial and engineering analysis. We’ve provided a checklist to help guide your evaluation:

- Define the Part’s Function and Requirements

- Assess load-bearing demands, tolerances, and structural needs

- Consider the end-use environment (temperature, pressure, chemicals)

- Identify any regulatory, industry, or safety compliance standards

- Evaluate Material Viability

- Determine whether high-performance thermoplastics can match or exceed metal performance

- Factor in long-term benefits like corrosion resistance and lighter weight

- Watch for exceptions where metal may still be the best choice (e.g., extreme stress or heat)

- Analyze Total Cost of Ownership

- Go beyond raw material costs — consider tooling, cycle times, maintenance, and longevity

- Calculate potential savings from reduced secondary operations (e.g., no welding, machining)

- Consider logistics and assembly advantages (e.g., fewer parts, lighter weight)

- Collaborate Early with Your Molding Partner

- Engage in early-stage design reviews to uncover risks and opportunities

- Use mold flow simulation and prototyping to validate performance before committing to tooling

- Align on part geometry, tolerances, and finishing requirements from the start

- Leverage Ferriot’s Expertise

- Tap into Ferriot’s DFM and engineering support to identify the optimal resin for your application

- Gain insight on balancing cost, performance, and manufacturability

- Partner with a team experienced in metal-to-plastic conversion across medical, industrial, and electronics sectors

By checking all these boxes, you can confidently determine whether a metal-to-plastic conversion will result in real, long-term ROI.

How Ferriot Supports Metal-to-Plastic Parts Conversion

Converting metal components to plastic requires more than just swapping materials — it takes strategic engineering, the right resin selection, and a manufacturing partner who understands the full picture. At Ferriot, we bring together all of these elements to ensure your conversion project is successful from start to finish:

- In-House Engineering Expertise — Ferriot’s engineers collaborate early in the design process to ensure your part is optimized for manufacturability. Our use of mold flow simulation and design for manufacturability (DFM) analysis helps identify potential issues before tooling begins, reducing risk and keeping projects on track.

- Material Selection Support — With deep knowledge of thermoplastics, engineering resins, and specialty materials — including UL-listed and high-heat polymers — Ferriot guides OEMs in selecting materials that meet performance, environmental, and regulatory demands.

- End-to-End Manufacturing Capabilities — From injection molding to assembly, finishing, and supply chain coordination, Ferriot provides full-service manufacturing under one roof. This integrated approach ensures quality, efficiency, and a smooth transition from metal to plastic parts.

- Proven Experience in Metal-to-Plastic Conversion — With decades of cross-industry experience, Ferriot has successfully converted countless metal parts to plastic — delivering lighter, more cost-effective, and equally durable components for complex applications.

Ready to explore the ROI of switching from metal to plastic?

Let Ferriot help you evaluate your part, select the right material, and move seamlessly into production. Contact us today to get started.