To properly benefit from the advantages of using structural foam parts in your product’s design, first, you need to understand the process.

Here’s how it works. The structural foam injection molding process uses a foaming agent (typically nitrogen gas or chemical blowing agent) added to a resin polymer as it melts, then injected into the standard injection molding tool (or die). In this process, the injection molding blowing agent activates and pushes resin uniformly into the cavity pockets; as the part cools, a solid skin forms against the mold. Inside the mold, the resulting foaming action produces a honeycomb-like structure behind the solid skin while reducing post-mold shrinking.

The resulting structural foam part is significantly lighter than other parts produced using other standard injection molding processes. The majority of structural foam parts utilize this injection molding method to reduce the overall weight of the part by up to 30%. However, lower weight isn’t the only advantage. Structural foam molding can provide several benefits you may want to consider as you plan your next project.

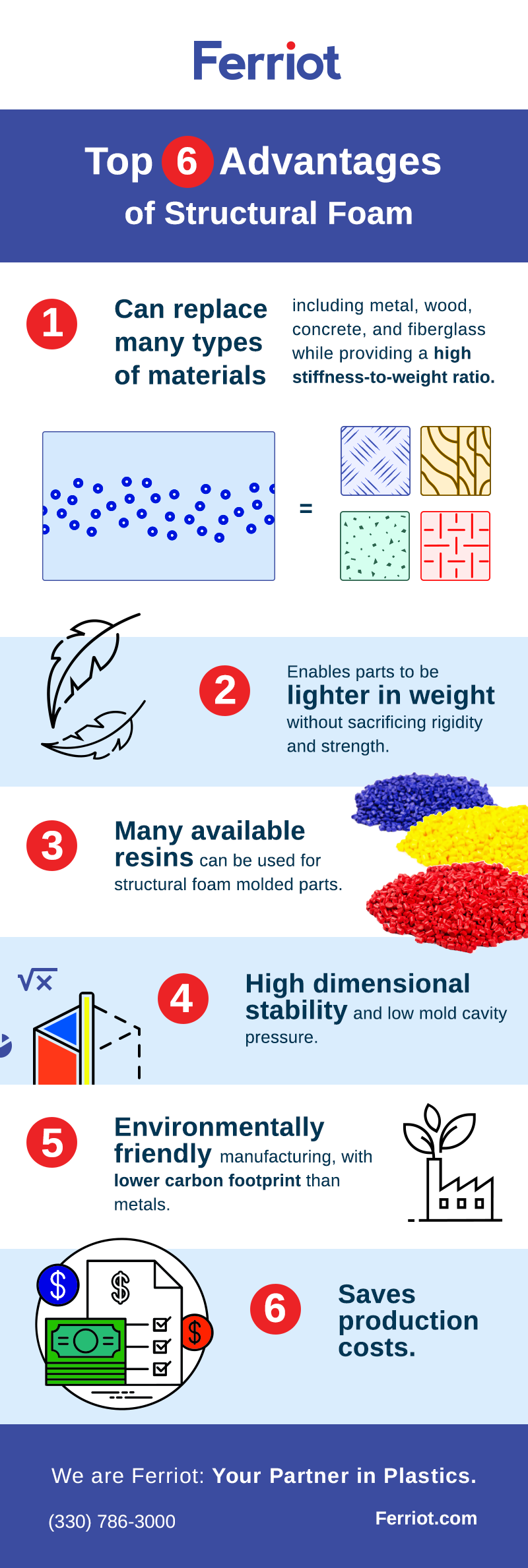

- Can replace many types of materials

Structural foam is increasingly replacing metal, wood, concrete, and fiberglass, primarily due to its ability to reduce a product’s overall weight while providing a high stiffness-to-weight ratio. - Lighter in weight

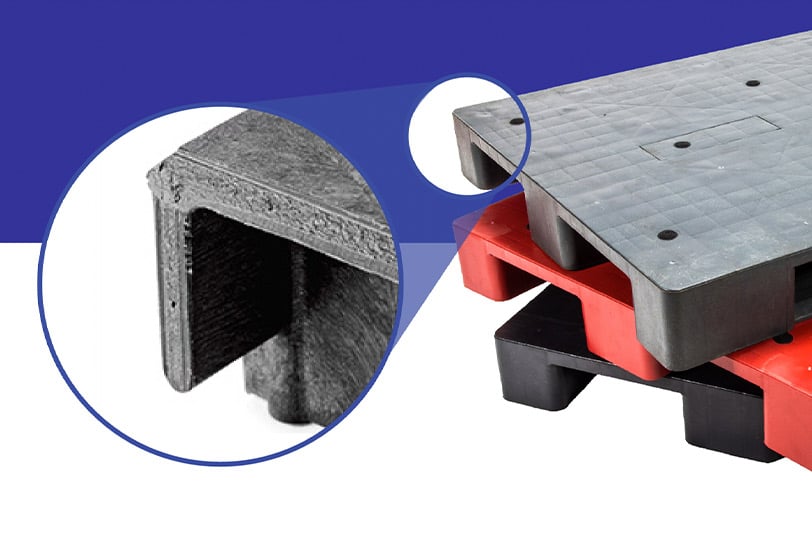

Due to the honeycomb, cellular composition resulting from the structural foam injection molding process, the finished parts have a high stiffness-to-weight and strength-to-weight ratio, enabling parts to be larger while weighing 10 to 30% less without sacrificing rigidity and strength. - Many available resins

Many resin polymers are available for manufacturing structural foam molded parts, including nylon, polycarbonate, ABS, PC/ABS, TPE, acrylic, acetol, polypropylene, polyethylene polystyrene, and PVC. To learn more about the various types of resins, view the resin selection webinar. - High dimensional stability

Controlling dimensional stability is important for all injection molded parts. Slight changes in dimensions can occur in all injection mold tools. However, due to the low mold cavity pressure and the resulting honeycomb-like structure, parts that use structural foam are typically more dimensionally stable as well as highly impact resistant. - Environmentally friendly

If available, it is possible to utilize recycled post-consumer resin materials in the structural foam injection molding process. The resulting parts that are produced are also able to be recycled at the end of the product’s lifecycle. Together, this helps reduce the overall carbon footprint of products. - Saves production costs

Using structural foam injection molded parts can reduce the cost of materials, tooling, and the overall production run. Tooling for structural foam molding can have the same level of detail as other injection mold tooling. Additionally, because the pressure is lower, it is possible to use aluminum tooling for the injection mold. The aluminum mold can last as long as steel molds because of the lower pressure being used.

The key to using structural foam parts successfully is in the ability to incorporate them into today’s complex custom mold designs. To learn more, download our whitepaper, Structural Foam Injection Molding Resources Guide.

To learn more, download the Structural Foam Injection Molding Resources Guide