Customers often ask us, can you paint plastic molded parts? The answer is yes, although painting molded plastic requires specialized knowledge, the proper equipment and an experienced staff. Special paints are required to give your parts the desired finish and ensure the paint bonds well with the plastic. However, painting techniques have evolved over the years and there are several different means by which the plastic parts can be painted to meet any need.

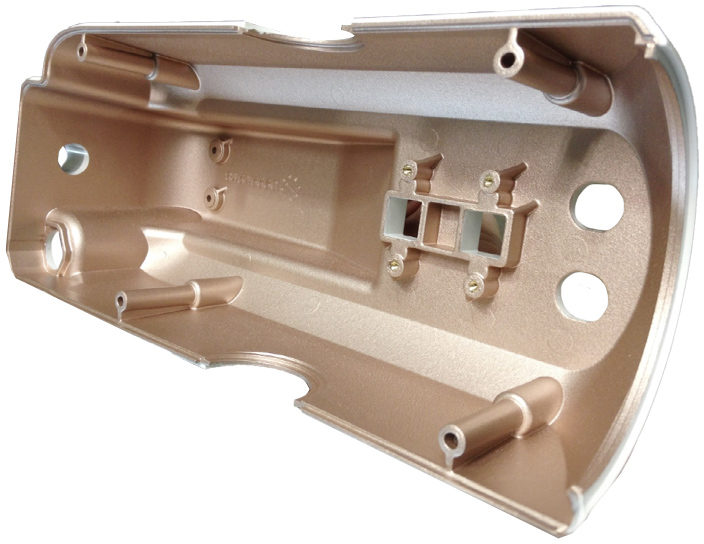

Molded plastic is typically painted using a multi-step process that involves surface preparation, primer application and topcoat painting. The plastic surface is cleaned and treated to ensure paint adhesion, followed by a primer application. Finally, the desired topcoat paint is applied in layers, before curing. Curing creates a durable, attractive finish.

There are two main reasons why painting molded parts provides a benefit to the customer:

1. Appearance

Painting a custom plastic part can significantly improve its appearance and offer several benefits for industrial manufacturers. Completely unrelated to functionality, the details below discuss options if you are looking for a flawless finish.

- ColorIf your pieces need to be uniform and you require a custom color, it will be less expensive and more pleasing to paint the pieces rather than create a custom colored resin. OEMs choose to have products painted because resins may not offer the desired effect or color.When it comes to testing painted plastic molded parts, color uniformity is the main thing that comes to mind. Paint will enhance the appearance of the plastic and will help you to match custom colors exactly.

- Mass CustomizationThis idea encompasses branding and customization. Manufacturers can paint a part to incorporate a customer’s branding elements, logos and unique designs onto a plastic part. This branding helps to distinguish products in the marketplace while also catering to specific customer preferences. Producing a variety of colors in a molding press is impractical, particularly when the plastic-colored parts that are required are small. Painting plastic can accomplish this purpose more easily and economically than colored resin.

- ImperfectionsPaint helps to conceal the imperfections of the mold and/or surface conditions that are a result of the injection molding process or part geometry. Some of the imperfections include:

- Blush: small imperfections that occur while the plastic fills the cavity.

- Filled resins: carbon or glass-filled resins cause white lines can have fibers on the surface of the part.

- Foaming agent: When molding structural foam parts, the surface is not typically cosmetically acceptable unless it is painted.

- High Gloss Finish

As a customer, you may want a higher gloss finish than the resin is capable of providing. Paints can achieve a wide range of gloss levels, which will make it easier to achieve your marketing objectives.

2. Functionality

While painting not only allows for improved aesthetics, the functionality of your plastic part can also be increased through painting, as described below:

- Stain ResistancePainting plastic can improve the protection of plastic molded parts from a broader range of chemicals and other substances that can stain it.

- Chemical ResistanceMost cleaning chemicals in the market today are harsh and can reduce the physical properties of some plastics over time. Paint helps to protect the plastic parts.

- Easy CleanThe smooth finish makes cleaning the plastic easy. There are no scratches or stains that would make it hard to clean or give dirt and dust a place to hide.

- Abrasion/Scratch ResistancePaint makes the plastic surface harder so that it will not be as easily scratched, helping to avoid abrasions.

- Surface ProtectionPainting provides a protective layer over the plastic surface, helping to shield it from environmental factors like UV radiation, moisture, and chemicals. This can extend the lifespan of the plastic part and improve its durability.

- Improved Surface TexturePainting can also help improve the surface texture of plastic parts by filling in imperfections, reducing roughness, and providing a smoother and more desirable feel.

- WeatherabilityUV coating is a perfect choice if your plastic parts will be used outside. A number of plastics are sensitive to exposure to sun, ozone, salt, and acids. Paint will help to protect the plastic.

One final reason for painting a custom plastic part that falls outside of appearance or functionality is regulatory compliance. In some industries, regulatory standards may require products to meet safety, environmental, or health regulations. Painting can help manufacturers ensure compliance in industries where regulatory standards require this treatment. An example would be the application of EMI/RFI shielding to the interior of a plastic electronic enclosure. This coating would absorb or reflect electromagnetic radiation to protect the device or other devices close by. This is widely used for medical devices.

Understanding the effects of painting plastics is a key to improving the appearance and performance of your molded plastic part. The ability to paint custom plastic parts serves as a versatile tool for industrial manufacturers seeking to elevate their products’ appearance, durability, and marketability.

Whether it’s adding a pop of color, incorporating branding, or enhancing protective qualities, painting can be a game-changer in various industries. By harnessing the power of paint, manufacturers can not only meet customer expectations but also unlock opportunities for innovation, cost savings, and compliance with regulatory standards.

As the world of plastics continues to evolve, painting remains a time-tested technique to transform plastic parts into polished and appealing components that make a lasting impression on consumers and clients alike.

In addition to tool design and injection molding, Ferriot offers a variety of value-added services such as painting or electromagnetic (EMI) shielding. These services provide turnkey product solutions for customers under one roof that meet functional requirements and satisfy aesthetic expectations.