In our previous article, Is it Time to Break Up with Your Custom Injection Molder?, we addressed missing deadlines, cost overruns, and quality issues as three primary reasons for deciding to move to a new supplier by transferring your mold tools.

However, before making such a significant leap of faith, you must be careful not to jump from the frying pan into the fire. As a first step, take time to understand the “Mastering the Shift: 7 Key Points for Smooth Injection Molding Supplier Transitions.”

While it seems common sense that the most critical key to success is maintaining complete transparency throughout the transfer process, it is surprising how many times that does not happen. Understandably, to accomplish that level of transparency, open and honest communications must exist between the mold owner and the potential new supplier. The harsh reality is that, sometimes, the mold owner can be the source of their headaches through miscommunications and “errors of omission” (intentional or unintentional).

Managing mold transfers

At Ferriot, we have been managing mold tool transfers for many years and pride ourselves in meeting and exceeding client expectations when we deliver finished parts to these clients. However, we’ve had some mold tool transfer challenges over the years and experienced several things that cause mold transfers to not work out so well. We know that if a customer wants to move a mold to us, it is usually not for a good reason.

Reasons can include:

- The tool was poorly designed and produces poorly molded parts.

- Unmanufacturable part designs yield subpar or even unusable parts.

- Customer is not paying bills in a timely manner.

- Uncooperative molders that have capacity issues.

- Unyielding customers with unrealistic demands.

Ultimately, everyone looking to transfer a mold wants to be completely satisfied with their finished product in every way, but for some reason, they are not. That’s why we’re here. Being open about any existing mold tooling problems and understanding the need to invest in corrections or improvement are two things that cannot be ignored.

Many problems begin when the company transferring the mold is unwilling to invest the money necessary to make the necessary corrections or improvements.

However, as is the case with most business challenges, the problems are rarely one-sided. For example, ask any custom injection molded parts customer whether they have had issues with a molder, and they laugh at the thought. Some may even respond, “Too many!”

Despite the issues, for many mold owners, even the thought of moving work is a tremendous pain, and there are numerous reasons to avoid it. For example, forecasting the current and near-term demand and then building a bank while keeping it from the current molder. Then, there’s paying to move the tool, hoping it is not damaged in transit. Assuming the tool makes it successfully in one piece to the supplier, there are the costs and time associated with requalifying parts at the new supplier. Some decide, “Maybe it’s better to stay with the devil I know than move things to the devil I don’t.”

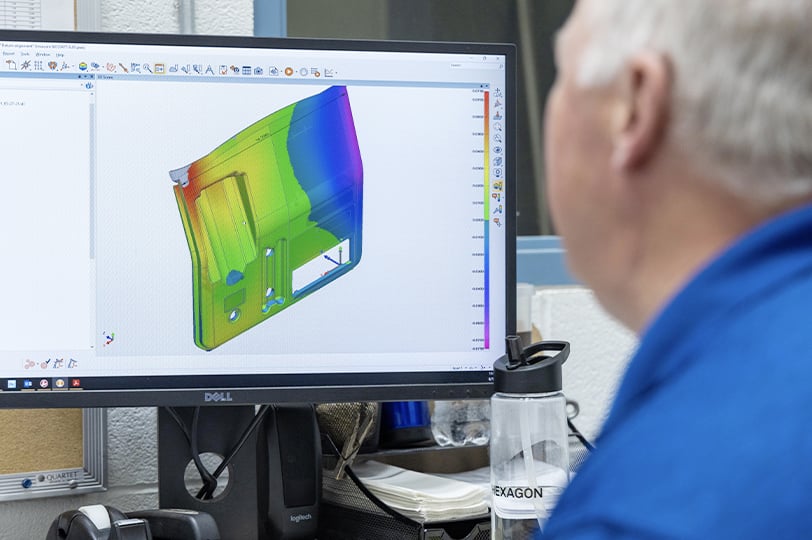

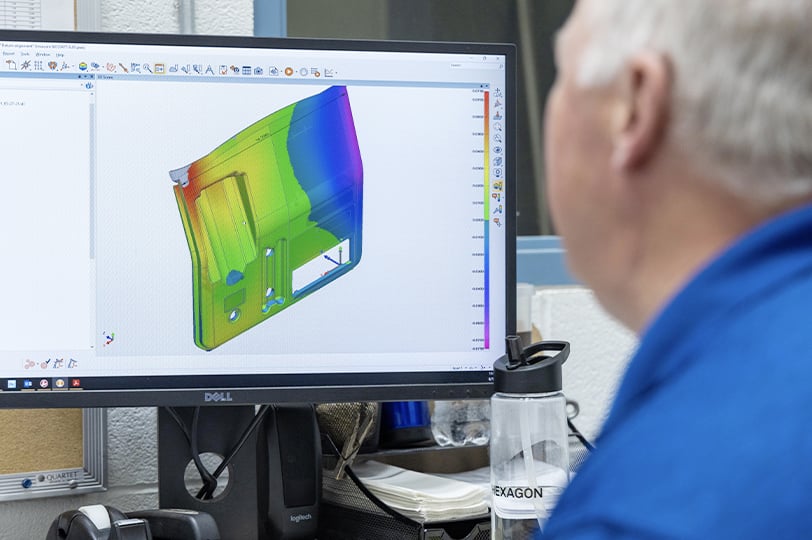

At Ferriot, we understand these concerns, and our Mold Tool Transfer Team works very hard at maintaining transparency and keeping the lines of communication open, knowing that the devil is, in fact, in the details. More and more mold owners have learned that transferring their molded parts requirements to us is wise; we specialize in highly engineered custom parts with highly engineered resin. In our tenth decade, experience has taught us the accurate and fair cost of providing parts to customers on time and to exact specifications.

And that brings us to the biggest headache: After all the time and effort, some companies look at the tooling and piece part price only. Awarding work this way can be a mistake. Understanding the lifetime value of the tool is important as well as the details on how the molder came to their pricing. Also once you have selected your molder, the DFM phase is where some part redesign will more than likely be needed. Collaboration with a team you can work well with is key. The most important work is done up front and will save money in the long run.

However, we know that will be the first and not the last we hear from many mold owners. They eventually realize their mistake, and after tens of thousands of dollars and tons of angst after a year or so, they call us to help fix it.

Ferriot can fix it, but if you want to save money and hassle, trust us up-front. Or trust us later.

Learn more:

- Is it Time to Break Up with Your Custom Injection Molder?

- ShopTALK: Mold Transfer Considerations Everyone Should Know

- Are you ready for your mold transfer? [Tool Transfer Success Checklist]