Part 2: The importance of communication in overcoming challenges and mitigating risk

Liz: What are some interesting challenges you faced on one of the recent mold transfer projects?

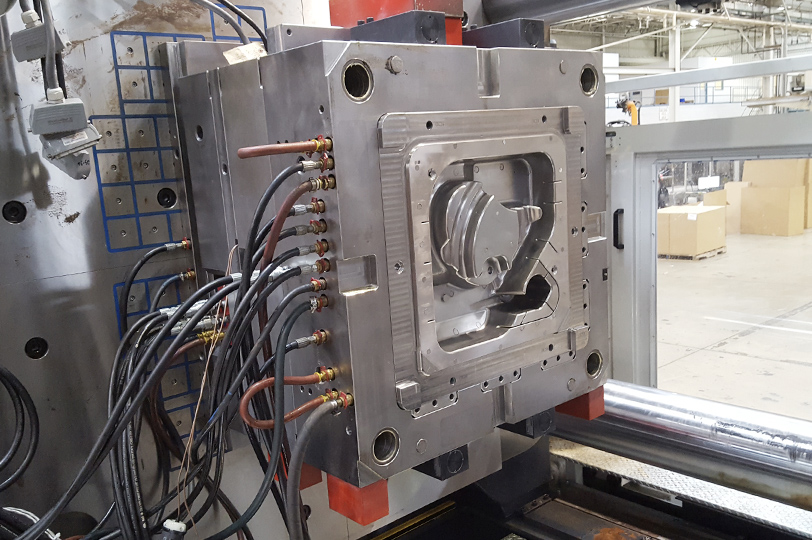

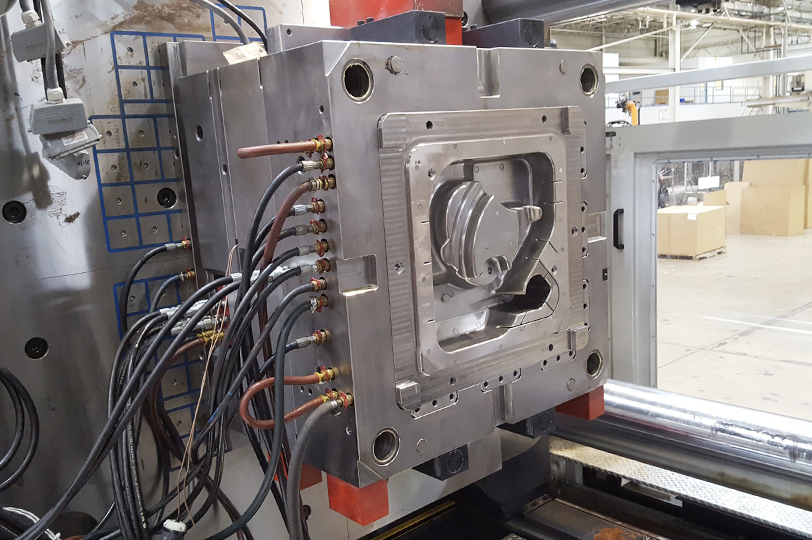

Amy: We accepted a transferred tool from one of our largest customers. Another molding company designed it. We were still determining what we were getting ourselves into exactly when we accepted this tool. For one thing, the tool is relatively large. It was designed to be able to make eight different parts inside this tool. There are five cavities possible to make eight different parts from these five cavities. In theory, it sounds like a great idea; you would use runner shutoffs and transfer the plastic material to produce another one of the parts in this tool. However, because of the tool size, it must go on a large press with a large barrel. A barrel is what holds the plastic. The biggest challenge with this, and there are many, is that one of the parts in this large tool only weighs 28 grams.

To try to produce this one 28-gram part out of this large tool, with plastic that sits in the barrel for hours and hours, it’s just not possible to do. So, we learned the hard way that we could only produce this part within spec by sacrificing a larger part to get the proper material flow into the tool we needed. And that raised the price of this part from approximately $2 to $10, which our customer was not happy about.

To try to produce this one 28-gram part out of this large tool, with plastic that sits in the barrel for hours and hours, it’s just not possible to do. So, we learned the hard way that we could only produce this part within spec by sacrificing a larger part to get the proper material flow into the tool we needed. And that raised the price of this part from approximately $2 to $10, which our customer was not happy about.

Liz: Are there common shortcuts that mold makers take that our customers should be aware of that, “Hey, be careful if somebody says, ‘We’re going to do it this way,’ because this can get you into trouble or can cause a problem in the future”?

Amy: Well, there’s just a lot of unknowns until we receive the transferred tool. We request drawings or 3D models of the tool in advance. However, we always need to find out if we’re getting the most updated version of that tool’s drawings and models. It’s common for the tool design not to be updated as the part design gets updated. So, we only know what we have once it gets here at Ferriot.

Liz: Really? The physical tooling could have been changed, and the spec drawings or whatever were not changed to reflect that?

Amy: Absolutely. It can be a revision control nightmare.

Liz: What is the most common reason a mold owner would arrange to transfer their mold tooling?

Amy: We often don’t know. The mold owners often don’t want to be transparent with us about the problems they’re having with their current supplier. They’re either experiencing quality issues, delivery issues, costing issues, or a combination.

Jerry: Agreed. It’s usually because either the customer is having trouble with their current supplier’s quality, delivery, or something else, or the current supplier just has told them they want to get rid of it. One of the parties is having trouble and needs to move the tool.

Liz: What are some reasons the current supplier would want to get rid of it? Slow-paying customers, things like that?

Amy: Low volume orders, price issues, or too much scrap.

Liz: We’ve also done that, where we’ve told customers to take their tools elsewhere. Many times, these might be legacy customers moving on to new products and suppliers, and we’re being used to produce service parts for the old products. We’ve lost the business, and it’s not worth our effort to continue to run small orders for them, and it’s ending a business relationship.

Who are the key players on our Mold Tool Transfer Team? Then, beyond the project manager, who do you typically work with on the customer side?

Jerry: It works best to involve the customer’s project manager, product engineer, and quality engineer. We need the complete history of the tool, how it’s designed, and the product requirements. It doesn’t work well when the only person involved on the client side is the purchasing procurement people. They tend to know little about the tool, the part, or anything else; they’re just trying to get the business transferred. Period. And they don’t know anything technical about the tool, nor do they know much of anything about the finished part.

Amy: Optimally, our team typically includes the project manager, tooling manager, quality manager, and a process engineer. That is ideal.

Liz: A great deal of these processes’ hinges on good communication. There are also a lot of details that need to be reviewed, revised or even replaced with process improvements. It’s a lot of servicing the business relationship.

Jerry: Absolutely. Another excellent example of a tool transfer that went well is the tool that came from Swaco. Amy would agree with me. It was a lot of work and effort, but we had all those people pretty much in alignment. We had their process engineer; we had their support from their engineering and quality organization. We knew what we were getting—no hidden problems. We could talk back and forth many times to get the tool up and running. It went very well, and we have a profitable product that we’re able to ship them parts.

Amy: That is a good example, Jerry. Initially, there were some growing pains, but you’re right; the customer was very supportive. They have injection presses of their own, so they’re very familiar with injection molding, which helps tremendously. They were willing to come on-site and help us evaluate the first production parts. They’ve been very good to work with because they have molding experience.

Liz: Were you guys involved more on the front end before the decision in this case? Or was it just good to have those people helping you after the decision was made?

Jerry: There was good front-end support when we were quoting the receipt of the tools. So, we had a reasonably good idea of what we were getting. But then, to Amy’s point, what helped was, when the tool came, we had access to their process engineer, product engineer, and quality engineer. And we worked as a team to get it up and to run and resolve the issue. There was no shortage of work to do and no shortage of effort, but it all went very well because it was a team effort.

Jerry: On other transfers, the buyer arranges them.

Liz: I can see it is difficult because if you’re getting a tool from another injection molder, they’re either happy to see it go, or they’re not happy to see the business go. As a result, you don’t necessarily have access to the necessary assistance either way.

Amy: Definitely. It’s a tricky business for customers to get information from their supplier that they’ve never asked for before, like mold designs, process sheets, and things like that. That throws up some flags with their current suppliers, and it sure would if it was asked of us. And there can be a reluctance to share that information for whatever reason.

Liz: Is it a suggested best practice for OEM mold owners to request that information from a molder when they start doing business and setting up new tooling as a form of risk mitigation?

Jerry: I think it’s typical. If our customer asked us to provide the mold design, we certainly would do that because they own it. There’s no question about it. If we built them a mold, they would own it. We provide them with the design, the 3D CAD, and everything if they want it. However, providing the process sheets, that’s different. We’d have to think about that. How important is the customer? That is proprietary information to us. That’s how we run that tool. But we’d likely ultimately provide it, especially to a large important customer who understands molding operations.

Liz: Yeah. I could see a company; even if they’re going to stick it in a file somewhere, it’s just part of owning the tool and mitigating risk just to have the information.

Jerry: Correct. We sometimes run into a problem when a customer is transferring tools to us. If they have it at a different molder, they’re sometimes reticent to get the mold design and process information from their current supplier because that would be tipping their hand that they’re just about to move that mold.

Summary

Mold tool transfer projects can pose unique challenges, with one of the main difficulties being the unknowns that come with receiving a transferred tool. While OEM mold owners can request drawings and 3D models in advance, there is no guarantee that they will receive the most updated version of a tool’s design over time. This issue can lead to problems with producing parts within spec, as well as revision control nightmares. Good communication is critical, and it is essential to have a team involved from both the mold owner’s and supplier’s sides, including project managers, product engineers, and quality managers, to mitigate these risks.

In part three of this article, I’ll review a few additional mold tool transfer success stories with our team of experts. We will discuss some challenges that we faced with our customers, how we addressed those challenges, and the end results that Ferriot’s solutions team delivered.

To learn more about mold transfer considerations, download the “Mastering the Shift: 7 Key Points for Smooth Injection Molding Supplier Transitions“ white paper.

Learn more:

- ShopTALK: Mold Transfer Considerations Everyone Should Know – Part 1

- Is it Time to Break Up with Your Custom Injection Molder?

- Are you ready for your mold transfer? [Tool Transfer Success Checklist]